XLG Series

- Output Voltages to 130kV

- Ground Referenced Filament Supply

- “Hot Anode”, Positve Polarity

- Local & Remote Programming

*Note: All specifications are subject to change without notice. Please consult the English PDF version of this datasheet for the most up-to-date revision.

3-260W Industrial X-Ray Generators

Spellman’s XLG Series of X-Ray generators are well regulated high voltage power supplies with output voltages to 130kV and very low ripple achieved through the use of advanced resonant conversion techniques. Extremely stable voltage and emission current outputs result in significant performance improvements over previously available technology.

The XLG Series provides all the power, control and support functions required for X-Ray applications including a regulated dc filament supply. These units incorporate local and remote programming, monitoring, safety interlock, short-circuit and overload protection.

Typical applications:

- Plating Measurement X-Ray generator

- Mineral Analysis X Ray generator

- X-Ray Fluorescence X-Ray high voltage power supply

Specifications

(Ref. 128012-001 REV. M)

SPECIFICATIONS

Input Voltage:

115Vac±10%, 50-60Hz single phase or

220Vac±10%, 50-60Hz single phase.

Voltage and Current Control:

Local: continuously adjustable from zero to maximum rating via a ten-turn potentiometer with a lockable counting dial.

Remote: 0 to +10Vdc proportional from 0 to full output. Accuracy: ±1%. Input Impedance: 10Mohm.

Filament:

Specify at time of order:

FH: 9A, 3V.

FL: 3A, 3V.

Preheat level is 0.45 amps in standby

Voltage Regulation:

Load: 0.005% of full output voltage no load to full load.

Line: 0.005% for input voltage range change.

Current Regulation:

Load: 0.05% of full current ±100µA from 0 to full voltage.

Line: 0.05% of rated current over specified input range.

Ripple:

0.03% rms below 1kHz.0.75% rms above 1kHz.

Temperature Coefficient:

100ppm/°C.

Stability:

0.01%/8 hrs after 1/2 hour warm-up.

0.02% per 8 hours (typical).

Cooling:

Free air convection.

Metering:

Digital voltage and current meters (3.5 digits), 1% accuracy.

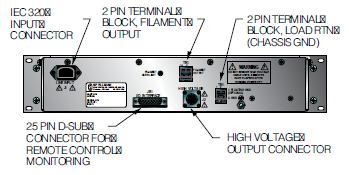

HV Output Cable:

10’ (3.3m) of shielded HV cable removable at rear.

I/O Connectors:

25 pin D-type for control interface with mating connector provided.

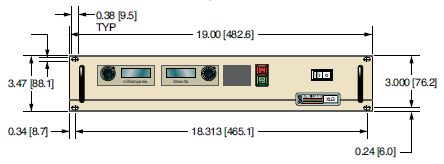

Dimensions:

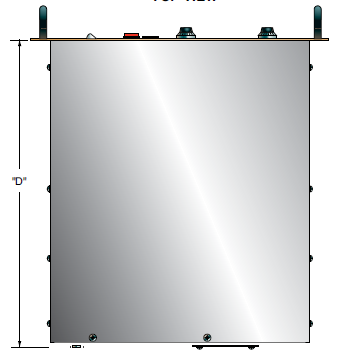

30 to 60kV: 3.5”H x 19”W x 19”D (8.9cm x 48.3cm x 48.3cm).

80 to 130kV: 3.5”H x 19”W x 24”D (8.9cm x 48.3cm x 61.0cm).

Regulatory Approvals:

Compliant to EEC EMC Directive. Compliant to EEC Low Voltage Directive.

FRONT PANEL STATUS INDICATORS:

Overvoltage Voltage Control Mode

Overtemperature Current Control Mode

Regulation Error Interlock Open

Arc Interlock Closed

HV ON: Red HV OFF: Green

OPTIONS

APT - Adjustable Power Trip

AT - Arc Trip

SS(x) - Non-Standard Slow Start

NSS - No Slow Start

IO - Instant ON

LL(x) - Extra Length HV Cable

SL - Slides

Electronic Component (Power Source)

XLG series is intended for installation as a component of a system. It is designed to meet CE standards, with conditions of acceptance often being: customer provided enclosure mounting, EMC filtering, and appropriate protection, and isolation devices. The XLG series is not intended to be operated by end users as a stand-alone device. The XLG series power supply can only be fully assessed when installed within a system, and as a component part within that system.

XLG INPUT CURRENT

| Model | 115Vac | 220Vac |

|---|---|---|

| 3W-30W | 0.6A | 0.3125A |

| 40W-60W | 1.2A | 0.625A |

| 70W-150W | 3.0A |

1.56A |

| 160W-260W | 5.25A |

2.71A |

XLG SELECTION TABLE 0.1mA, 0.2mA , 0.5mA

| kV | 0.1mA | 0.2mA | .5mA |

|---|---|---|---|

| 30 | XLG30P3* | XLG30P6* | XLG30P15* |

| 35 | XLG35P3.5* | XLG35P7* | XLG35P17.5* |

| 40 | XLG40P4* | XLG40P8* | XLG40P20* |

| 50 | XLG50P5* | XLG50P10* | XLG50P25* |

| 60 | XLG60P6* | XLG60P12* | XLG60P30* |

| 80 | XLG80P8* | XLG80P16* | XLG80P40* |

| 100 | XLG100P10* | XLG100P20* | XLG100P50* |

| 120 | XLG120P12* | XLG120P24* | XLG120P60* |

| 130 | XLG130P13* | XLG130P26* | XLG130P65* |

*Specify FH for High power (27W) filament, FL for Low power (9W) filament.

XLG SELECTION TABLE 1.0mA, 2.0mA, 3.0mA

| kV | 1.0mA | 2.0mA | 3.0mA |

|---|---|---|---|

| 30 | XLG30P30* | XLG30P60* | XLG30P90* |

| 35 | XLG35P35* | XLG35P70* | XLG35P105* |

| 40 | XLG40P40* | XLG40P80* | XLG40P120* |

| 50 | XLG50P50* | XLG50P100* | XLG50P150* |

| 60 | XLG60P60* | XLG60P120* | XLG60P180* |

| 80 | XLG80P80* | XLG80P160* | --- |

| 100 | XLG100P100* | XLG100P200* | --- |

| 120 | XLG120P120* | XLG120P240* | --- |

| 130 | XLG130P130* | XLG130P260* | --- |

*Specify FH for High power (27W) filament, FL for Low power (9W) filament.

XLG CONNECTOR 25 PIN

| Pin | Signal | Signal Parameters |

|---|---|---|

| 1 | Power Supply Common | Signal Ground |

| 2 | External Inhibit | Ground=Inhibit, Open=HV On |

| 3 | External Interlock | +15V at Open, <15mA at Closed |

| 4 | External Interlock Return | Return for Interlock |

| 5 | Current Monitor | 0 to 10V=0 to 100% Rated Output |

| 6 | kV Test Point | 0 to 10V=0 to 100% Rated Output |

| 7 | +10V Reference | +10V, 1mA Max |

| 8 | Remote Current Program In | 0 to 10V=0 to 100% Rated Output |

| 9 | Local Current Program Out | Front Panel Program Voltage |

| 10 | Remote Voltage Program In | 0 to 10V=0 to 100% Rated Output |

| 11 | Local Voltage Program Ou | Front Panel Program Voltage |

| 12 | Power Monitor | 0 to 10V=0 to 100% Rated Output (Optional) |

| 13 | Remote Power Program I | 0 to 10V=0 to 100% Rated Output (Optional) |

| 14 | Local HV Off Out | +15V at Open, <25mA at Closed Connect to HV OFF for Fp Operation |

| 15 | HV Off | +15V at Open, <25mA at Closed Connect to HV OFF for Fp Operation |

| 16 | Remote HV On | +15V, 10mA Max=HV Off 0=HV On, +15V, 10mA Max=HV Off |

| 17 | Remote HV Off Indicator | +15V, 10mA Max=HV Off 0=HV On, +15V, 10mA Max=HV Off |

| 18 | Remote HV On Indicator | 0=HV Off, +15V, 10mA Max=HV O |

| 19 | Remote Voltage Mode | Open Collector 50V Max, 10mA Max On=Active |

| 20 | Remote Current Mode | Open Collector 50V Max, 10mA Max On=Active |

| 21 | Remote Power Mode | Open Collector 50V Max, 10mA Max On=Active |

| 22 | Remote PS Fault | 0=Fault, +15V, 0.1mA Max=No Fault |

| 23 | +15V Output | +15V, 100mA Max |

| 24 | Power Supply Common | Signal Ground |

| 25 | Shield Return | Shield Return |

Tables & Diagrams

DIMENSIONS: in.[mm]

FRONT VIEW

TOP VIEW

BACK VIEW

Frequently Asked Questions

Application Notes AN-12 – The Benefit of Using a Current Source to Power X-Ray Tube Filament Circuits

Application Notes AN-13 – Arc Intervention Circuitry and External Series Limiting Resistors

Application Notes AN-14 – The Limits of Front Panel Digital Meters

Application Notes AN-15 – 3.5 And 4.5 Digit Meter Displays Explained

Application Notes AN-23 – SL HV Off and HV on Circuitry Explained

Application Notes AN-01 – Fundamentals of X-Ray Generator – X-Ray Tube Optimization