PMX Series

- Custom Designed Specifically for Mammography Applications

- Compact Space Saving Modular Format

- Fast Rise and Fall Times Help Minimize Unnecessary Patient Radiation Exposure

- Dual Speed Starter, Boost/Brake Capability

- RS-232 and Optional Ethernet Interfaces

*Note: All specifications are subject to change without notice. Please consult the English PDF version of this datasheet for the most up-to-date revision.

Spellman PMX Series 50kV X-Ray Generator

Spellman’s PMX is a high performance X-Ray generator designed specifically for mammography applications including FFDM and DBT. It features 2 and 3 point exposure modes as well as smart AEC with a pre-exposure.

The PMX is a 5kW high frequency X-Ray generator integrated with a dual filament power supply, and a dual-speed X-Ray tube starter. Due to the PMX's superior power conversion technology and inverter design it can provide stable and accurate X-Ray tube high voltage with fast rise and fall times.

Smooth system integration of the PMX is accomplished through the use of RS-232 and optional Ethernet digital interface, pre-loaded X-Ray tube parameters, easy access interlocks and I/O connections, and internal generator diagnostics. Optional GUI utility software is also offered to help with initial system integration.

사양

(Ref. 128113-001 REV. C)

Input Voltage:

200-240Vac (±10%), single phase, 50Hz/60Hz

Input Current:

Minimum 35A service recommended for 5kW operation

External EMC Filter (Schaffner FN2070-36-08-36A) required to meet CE/EMC specifications – Not provided

Mains Contactor – Not provided

Customer is responsible for mains safety disconnection.

Output (Tube) Voltage

Output Voltage Range:

20kV to 49kV

Polarity:

Positive, grounded cathode X-Ray tube

Accuracy:

2% (measured per IEC60601-2-45)

Reproductibility:

<0.5%

Rise Time:

<1ms to within 98% of the programmed voltage

Fall Time:

<10ms with a max HV cable length of 8 feet (2.4 meters)

Ripple:

≤ 4% p-p

Output (Tube) Current/Power:

Output Current Range:

10mA to 200mA

Output Power:

5kW @ 0.1 second loading time,

300 Watts maximum average power

Accuracy:

< ±10% on exposure less than 10ms (measured per IEC60601-2-45)

Rise Time:

<1ms to within 95% of the programmed mA value

Fall Time:

<10ms with a maximum HV cable length of 8 feet (2.4 meters)

Exposure Time (Loading Time):

Maximum Single Exposure Time:

10 seconds

Shortest Single Exposure Time:

5ms

Loading time accuracy:

±3% +1ms (measured per IEC60601-2-45)

Maximum mAs:

600mAs

Exposure Timer:

5mS-10 seconds

Accuracy:

< ±10% (measured per IEC60601-2-45)

Reproductibility:

<0.5%

Filament Configuration:

DC filament drive: self corrected filament preheat settings with closed loop emission control and smart learning algorithm

Filament Output:

0-6 amps at a compliance of 5.5 volts, maximum.

Dual Speed Starter:

High speed (180Hz) and low speed (60Hz) can be configured via the serial interface.

Boost and Brake capability provided.

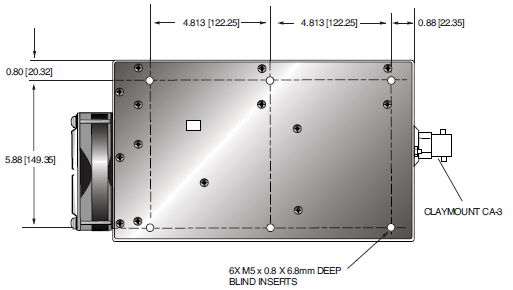

High Voltage Connector:

60kV, Claymount CA-3 type or equivalent

Communication Interface:

RS-232 standard, optional Ethernet

Grounding Point:

M5 ground stud provided on chassis

Environmental:

Temperature Range:

Operating: 10°C to 40°C

Storage: -40°C to 85°C

Humidity:

20% to 85% RH, non-condensing.

Cooling:

Internal fan

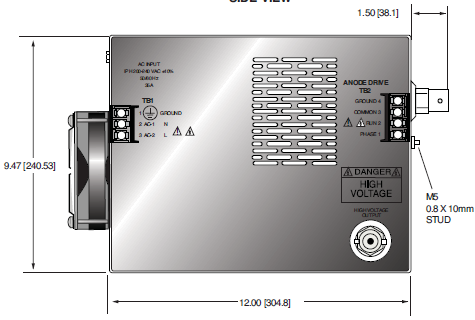

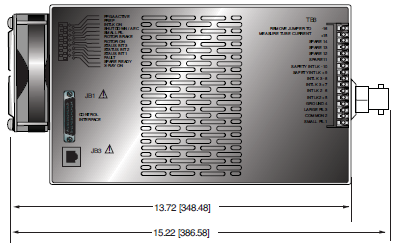

Dimensions:

9.47. H X 7.19. W X 13.72. D (240.5mm x 182.6mm x 348.5mm)

Weight:

<23 pounds (10.5kg)

Regulatory Approvals:

Designed to meet EMC:IEC 60601-1-2. UL/CUL recognized file E242584. RoHS compliant.

Application Features:

- 2 point/3 point exposure modes

- AEC/Smart AEC exposure modes

- Dual Speed Starter

- X-Ray tube anode heat calculator

- Preloaded X-Ray tube parameters and expandable X-Ray tube library

TB2 ROTOR INTERFACE

| Pin | Signal | Parameters |

|---|---|---|

| TB2-1 | Phase | To tube auxiliary winding |

| TB2-2 | Run | To tube principle winding |

| TB2-3 | Com | To tube common winding |

| TB2-4 | Ground | To tube housing ground |

PMX STANDARD SYSTEM INTERFACE— JB1 25 PIN MALE D CONNECTOR

| Pin | Signal | Parameters |

|---|---|---|

| 1 | GND | Signal Ground |

| 2 | +5Vdc Out | +5Vdc, 100mA max. |

| 3 | RS-232 Tx Out | RS-232 Transmit |

| 4 | RS-232 Rx In | RS-232 Receive |

| 5 | PREP | User signal (Contact Closure) to alert the generatorthat exposure sequence will begin. Once this signalis active, exposure parameters are locked in andcannot be changed. The generator enables thestarter to to boost the rotor. Contact connection to pin 24. Closed = PREP, the filament is placed inpreheat mode |

| 6 | READY | Generator signal to user to indicate the rotor runs tospeed and the generator is ready for X-Ray exposureOpen Collector. Low/Active = Ready |

| 7 | ROTOR SHUTDOWN | User signal to brake the rotor drive |

| 8 | EXPOSURE | User signal (Contact Closure) to generator to generate X-Rays. Filament is boosted, and highvoltage is generated after the boost time. Contactconnection to pin 24. Closed = Exposure |

| 9 | X-Ray ON 75% Status | Transistor output to indicate X-Ray ON statussynchronized with 75% of kVP setting point. |

| 10 | X-Ray ON Status | Transistor output to indicate X-Ray ON statussynchronized with kV start up. |

| 11 | N/C | N/C |

| 12 | X-Ray SHUTDOWN/AEC | User signal to generator to rapidly turn HV OFFand ON during serial exposure sequence |

| 13 | RS-232 ISO Ground | Isolated ground from RS-232 transceiver IC |

| 14 | HVG FAULT Status | Generator signal indicating generator fault. Opencollector transistor output. Low/Active = Fault |

| 15 | Status Bit 1 | 3 bit status lines for up to 6 status messages. separate matrix descibing functionality. Open Collector. Low/Active = Message |

| 16 | Status Bit 2 | |

| 17 | Status Bit 3 | |

| 18 | N/C | N/C |

| 19 | N/C | N/C |

| 20 | kV Monitor | Signal from generator. 0-10V = 0-50kV. Zout = 1kΩ |

| 21 | Emission Monitor | Signal from generator. 0-10V = 0-200mA. Zout = 1kΩ |

| 22 | Filament Current Monitor | Signal from generator. 0-10V = 0-6A. Zout = 1kΩ |

| 23 | Program/Monitor Return | Ground for reference of program and monitor signals |

| 24 | +24Vdc Out | For connection to PREP and EXPOSURE control relay coils |

| 25 | SHIELD/GND | For connection of interface cable shield to generatorchassis ground |

TB3 TUBE AND INTERLOCK INTERFACE

| Pin | Signal | Parameters |

|---|---|---|

| TB3-1 | SMALL FIL | Connection to tube small filament |

| TB3-2 | COMMON | Connection to tube filament common |

| TB3-3 | LARGE FIL | Connection to large filament |

| TB3-4 | GROUND | Generator chassis for cable shield connection |

| TB3-5 | Interlock 2+ | Used if tube has separate thermostat switch. Open = OVER TEMP. (short terminals if not used) |

| TB3-6 | Interlock 2- | |

| TB3-7 | Interlock 3+ | Used if tube has cooling circulator flow switch. Open = NO FLOW. (short terminals if not used) |

| TB3-8 | Interlock 3- | |

| TB3-9 | Safety Interlock+ | User signal (Contact Closure) for safety interlocks such as door interlocks. Open turns HV OFF, or inhibits HV from being generated.Closed = OK 24Vdc @ <1A typical |

| TB3-10 | Safety Interlock- | |

| TB3-11 | Contactor Coil+ | Option for contactor coil control |

| TB3-12 | Contactor Coil- | |

| TB3-13 | Spare | N/C |

| TB3-14 | Spare | N/C |

| TB3-15 | Tube Current+ | Tube current flows out from this pin |

| TB3-16 | Tube Current- | Tube current flows into this pin |

테이블 및 다이어그램

DIMENSIONS: in.[mm]

FRONT VIEW

SIDE VIEW

TOP VIEW

BOTTOM VIEW

Frequently Asked Questions

Application Notes AN-12 – The Benefit of Using a Current Source to Power X-Ray Tube Filament Circuits

Application Notes AN-01 – Fundamentals of X-Ray Generator – X-Ray Tube Optimization