STシリーズ

- シングル6U (10.5インチ) シャーシ

- モデル: 1kV~150kV

- リモートアナログ、リモートイーサネットインターフェイス

- 100kW超用パラレルユニット

- イーサネットインターフェイスでユーザー設定可能

*注: すべての仕様は予告なく変更される場合があります。最新版についてはこのデータシートの英語PDFをご覧ください。

12kW高電圧電源

スペルマンのSTシリーズ、12kW高圧電源装置は、正または 負の極性で20機種を取り揃え、1kV~225kVの出力をカバー します。機能満載のフロント・パネルはローカル制御しやすく、 また、拡張的なアナログ・インターフェースが包括的なリモート 制御能力を提供します。標準のイーサネットおよびRS-232デ ジタル・インターフェースにより、STをお客様のシステム設計 へ簡単に統合できます。

STの頑丈なIGBTインバータは本質的に無停止型で、半導体加工 や真空蒸着など厳しい用途に理想的です。多数の運転機能を、お客 様特有のご要求に合わせて構成できます。追加のシャーシを並列構 成することにより、100kWを超える出力電力が提供可能です。

用途

- イオンビーム注入

- 半導体加工

- 電子ビーム溶接

- コンデンサ充電

- 高出力RF送信機

- 電気集塵装置

- X線システム

![]()

Specifications

(Ref. 128077-001 REV. W)

SPECIFICATIONS

Input Voltage:

Standard: 180-264Vac, 50/60Hz, three phase, 90% efficiency, 0.85 power factor

Optional: 360-528Vac 50/60Hz, three phase (400Vac)

Input Current:

Standard: 180-264Vac, three phase; 50 amps, maximum

Optional: 360-528Vac, three phase; 25 amps, maximum

Output Voltage:

20 models from 1kV to 225kV. Each model is available with positive or negative outputs. 1kV to 10kV units are internally reversible.

Local Output Controls:

Voltage and current are continuously adjustable over entire range via ten-turn potentiometers with lockable counting dials.

Voltage Regulation:

Load: 0.05% of full voltage +500mV for full load change.

Line: 0.05%of full voltage +500mV over specified input range.

Current Regulation:

Load: 0.05% of full current ±100µA for any voltage change.

Line: 0.05% of full current over specified input range.

Ripple:

0.3% p-p +1Vrms. Lower ripple available via special order

Stability:

0.02%hr. after 1 hour warm-up.

Temperature Coefficient:

100ppm/°C. Higher stability (50ppm/°C) available on special order via the HS option

Environmental:

Temperature Range:

Operating: 0°C to 40°C

Storage: -40°C to 85°C

Humidity: 10% to 90% RH, non-condensing.

Cooling:

Forced air; inlet through side panels, outlet at rear panel

Metering:

Digital voltage and current meters, accurate to within 1%

System Status Display:

“Dead Front” type indicators provide status of up to 12 system operations including voltage and current regulation, fault conditions and circuit control.

Digital Interface:

Ethernet and RS-232 digital interface implemented with 12 bits of resolution. A VB GUI is provided.

Input Line Connector:

A 6 foot (1.8 meter) long captive line cord is provided.

Analog Interface Connector:

50 pin female D connector

High Voltage Output Cable:

1-150kV: A detachable 10’ (3.05m) long shielded HV cable is provided

225kV: R-28 type X-Ray connector. No output cable is provided

Dimensions:

10.5˝ (6U)H X 19˝ W X 21˝ D (266mm x 482mm x 533mm)

150kV: 10.5˝ (6U)H X 19˝ W X 23˝ D (266mm x 482mm x 584mm)

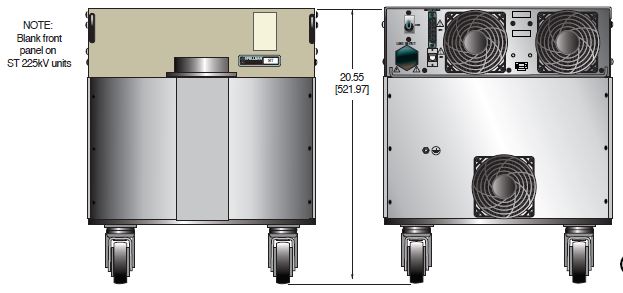

225kV: 20.55˝ H X 17.01˝ W X 29.7˝ D (521mm x 432mm x 754mm)

Weight:

1kV to 50kV: <100 pounds (45.36kg)

60kV to 120kV: <140 pounds (63.50kg)

150kV: <150 pounds (68.03kg)

225kV: <260 pounds (117.9kg)

Individual kV models may vary

Regulatory Approvals:

Compliant to EEC EMC Directive. Compliant to EEC Low Voltage Directive. RoHS Compliant.

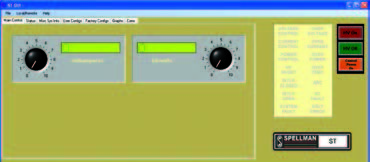

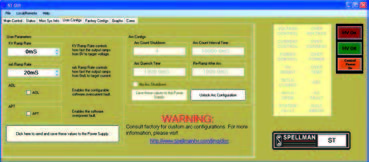

Digital Interface

The ST features a standard RS-232 and Ethernet digital interface. Utilizing these standard digital interfaces can dramatically simplify power supply interfacing requirements saving the user both time and money, while enhancing functionality and overall capability. Spellman provides a GUI with the ST that allows the customer to both customize operational features of the ST while also providing basic power supply operational features.

Main control screen

Status screen

User configuration screen

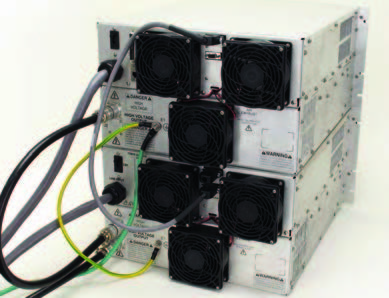

Parallel Capability

The ST series is designed to offer additional power capability by adding a chassis in parallel to create a main/secondary configuration providing up to and beyond 100kW’s. The main chassis is the point of connection for customer interfacing; this multichassis system effectively functions as a single power supply. The main unit retains the full featured front panel, while secondary units have a Blank Front Panel. To configure an orderable model number, simply use Spellman’s applicable base ST model number and increment the power denominator in 12kW steps as required:

ST60P24

This would be an ST with a 60kV, positive polarity, providing 24kW’s of power (2 chassis)

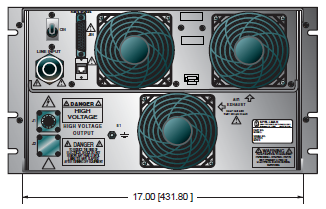

Rear panel showing connections for parallel operation:

Rear panel showing connections for parallel operation

Main/secondary 24kW ST

Arc Intervention

Spellman’s ST power supplies have an arc intervention feature that senses arc currents via a fast acting current sense transformer. The purpose of the arc intervention circuitry is to prevent power supply damage from continuous, long term arcing. The factory default configuration will trip off the unit with an Arc Fault if 4 arcs occur in a 10 second time period. Customers can change basic arc intervention parameters (Arc Count, Arc Quench, Reramp Time, and Window Time) within preset limits via the digital interface; customized units can be provided for unique arc prone environments, contact Spellman for details.

HARDWARE BASED OPTIONS

BFP - Blank Front Panel

HS - High Stability

LL(X) - High Voltage Cable Length

400VAC - 360-528Vac Input

SOFTWARE CONFIGURABLE FEATURES

Adjustable Overload Trip

Arc Trip Count

Arc Quench Time

Arc Re-Ramp Time

Constant Power Control

Adjustable Power Trip

Slow Start Ramp Times

Electronic Component (Power Source)

ST series is intended for installation as a component of a system. It is designed to meet CE standards, with conditions of acceptance often being: customer provided enclosure mounting, EMC filtering, and appropriate protection, and isolation devices. The ST series is not intended to be operated by end users as a stand-alone device. The ST series power supply can only be fully assessed when installed within a system, and as a component part within that system.

ST SELECTION TABLE

| Maximum Rating | Model Number | |

|---|---|---|

| kV | mA | |

| 1 | 12,000 | ST1*12 |

| 2 | 6,000 | ST2*12 |

| 3 | 4,000 | ST3*12 |

| 4 | 3,000 | ST4*12 |

| 6 | 2,000 | ST6*12 |

| 8 | 1,500 | ST8*12 |

| 10 | 1,200 | ST10*12 |

| 12 | 1,000 | ST12*12 |

| 15 | 800 | ST15*12 |

| 20 | 600 | ST20*12 |

| 30 | 400 | ST30*12 |

| 40 | 300 | ST40*12 |

| 50 | 240 | ST50*12 |

| 60 | 200 | ST60*12 |

| 70 | 171 | ST70*12 |

| 80 | 150 | ST80*12 |

| 100 | 120 | ST100*12 |

| 120 | 100 | ST120*12 |

| 150 | 67 | ST150*10 |

| 225 | 40 | ST225*10 |

*Substitute “P” for positive polarity and “N” for negative polarity. Polarity must be specified at time of order. 1-10kV units are inherently reversible by design requiring an internal wiring change to swap polarities. Intermediate voltage units are available by special order. 150kV units are limited to a maximum output of 10kW’s

NOTE: ST225 units cannot be paralled!

Parallel operation: Additional power can be provided in increments of 12kW’s by connecting chassis in parallel via the use of the ST’s main/secondary configuration.

Use the applicable base ST model number and increment the power denominated in 12kW steps as required.

ST10P24 10kV @ 24kW’s

ST10P36 10kV @ 36kW’s

ST10P48 10kV @ 48kW’s

ST 1-150kV rear panel view

ST 225V rear panel view

JB1 ST ANALOG INTERFACE—50 PIN FEMALE D CONNECTOR

| Pin | Signal | Parameters |

|---|---|---|

| 1 | Power Supply Common | Power Supply Ground |

| 2 | Reset/HV Inhibit | Normally open, Low = Reset/Inhibit |

| 3 | External Interlock | +24Vdc @ open, <25mA @ closed |

| 4 | External Interlock Return | Return for External Interlock |

| 5 | mA Test Point | 0-10Vdc = 0-100% rated output, Zout= 1KΩ, 1% |

| 6 | kV Test Point | 0-10Vdc = 0-100% rated output, Zout= 1KΩ, 1% |

| 7 | +10Vdc Reference Output | +10Vdc @ 1mA |

| 8 | mA Program Input | 0-10Vdc = 0-100% rated output, Zin>10MΩ |

| 9 | Local mA Program Output | 0-10Vdc = 0-100% rated output, front panel pot |

| 10 | kV Program Input | 0-10Vdc = 0-100% rated output, Zin>10MΩ |

| 11 | Local kV Program Output |

010Vdc = 0100% rated output, front panel pot |

| 12 | Remote Power On Output |

+24Vdc @ open, 2A peak, 1Adc @ closed |

| 13 | Remote Power On Return |

Return for Remote Power On |

| 14 | Remote HV Off | +24Vdc @ open, 2A peak, 1Adc @ closed, connect to pin15 for front panel operation |

| 15 | Remote HV Off/On Common |

HV On/Off Common |

| 16 | Remote HV On | +24Vdc @ open, 2A peak, 1Adc @ closed, momentarily connect to pin 15 enable high voltage |

| 17 | HV Off Indicator |

+24Vdc @ 25mA = HV Off |

| 18 | HV On Indicator | +24Vdc @ 25mA = HV On |

| 19 | Power Supply Common |

Supply Ground |

| 20 | +24Vdc Output | +24Vdc @ 100mA, maximum |

| 21 | Voltage Mode Status | Open Collector, Low = Active |

| 22 | Current Mode Status | Open Collector, Low = Active |

| 23 | Power Mode Status | Open Collector, Low = Active |

| 24 | Interlock Closed Status | Open Collector, Low = Active |

| 25 | Power Test Point | 010Vdc = 0100% rated output, Zout= 5KΩ, 1% |

| 26 | Spare | |

| 27 | Spare | |

| 28 | Remote Overvoltage Adjust |

010Vdc = 0100% rated output |

| 29 | Over Power Fault | Open Collector, Low = Active |

| 30 | Over Voltage Fault | Open Collector, Low = Active |

| 31 | Over Current Fault | Open Collector, Low = Active |

| 32 | System Fault | Open Collector, Low = Active |

| 33 | RGLT Error Fault | Open Collector, Low = Active |

| 34 | Arc | Open Collector, Low = Active |

| 35 | Over Temp Fault | Open Collector, Low = Active |

| 36 | AC Fault | Open Collector, Low = Active |

| 37 | Spare | |

| 38 | Spare | |

| 39 | Spare | |

| 40 | Spare | |

| 41 | Spare | |

| 42 | Remote Power Program Input | 010Vdc = 0100% rated output, Zin>10MΩ |

| 43 | Local Power Program Output |

010Vdc = 0100% rated output, internal pot |

| 44 | +5Vdc Output | +5Vdc @ 100mA, maximum |

| 45 | +15Vdc Output | +15Vdc @ 100mA, maximum |

| 46 | 15Vdc Output | 15Vdc @ 10mA, maximum |

| 47 | RS232 Tx | |

| 48 | RS232 Rx | |

| 49 | RS232 GND | |

| 50 | Power Supply Common | Power Supply Ground |

Tables & Diagrams

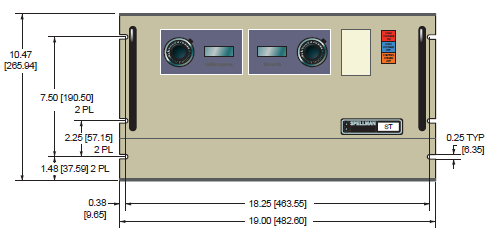

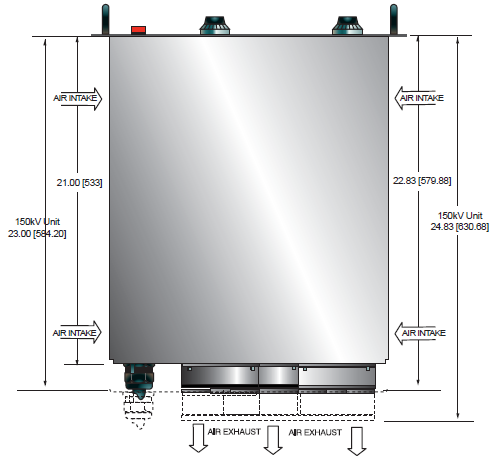

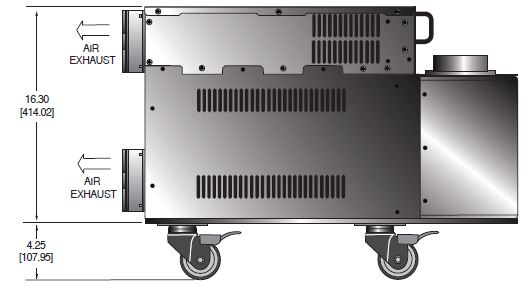

DIMENSIONS: in.[mm]

ST 1kV-150kV

FRONT VIEW

TOP VIEW

BACK VIEW

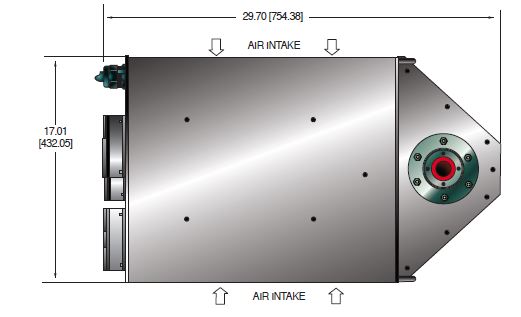

DIMENSIONS: in.[mm]

ST 225kV

TOP VIEW

SIDE VIEW

FRONT VIEW REAR VIEW

Frequently Asked Questions

What Is a Safe Level of High Voltage?

What Is an “External Interlock”?

Where Can I Obtain Information on High Voltage Safety Practices?

What Do You Mean That the Output Side of the High Voltage Cable on Most Standard Products Is “Unterminated”?

How Should I Ground Your Supply?

Why Is Arcing an Issue for a High Voltage Power Supply?

Application Notes AN-13 – Arc Intervention Circuitry and External Series Limiting Resistors

Application Notes AN-14 – The Limits of Front Panel Digital Meters

Application Notes AN-15 – 3.5 And 4.5 Digit Meter Displays Explained

Application Notes AN-16 – Parallel Capability of the ST Series

Application Notes AN-18 – Current Loop/Arc Detection Circuitry

Application Notes AN-19 – High Voltage Cable Lengths Discussed