EBM-FEG

- 電界放出SEM用のTetrode電源を統合

- 非常に低いリップルと超安定出力

- 堅牢なアーク及び短絡保護

- 微小放電イベントを最小限に抑える設計

- 光学的に絶縁されたデジタルインターフェース

- テストおよび開発作業用の無料GUI

- UL認証、CEマーク、およびSEMIS2に適合するよう設計

*注:すべての仕様は予告なく変更される場合があります。 最新のリビジョンについては、このデータシートの 英語版PDFを参照してください。

SEMアプリケーション向けOEMモジュール

スペルマンのEBM-FEGシリーズは、走査型電子顕微鏡(SEM)カラムを駆動するために特別に設計された、統合された複数出力の高圧電源です。スペルマンの広範なアプリケーション知識により、SEMの厳しい要件を満たすようにカスタマイズできる、さまざまなテクノロジープラットフォームを開発することができました。

主な加速電圧は安定性の高い30kV電源であり、19インチラックに取り付けるエクステンダーを備えたコンパクトなソリューションで電界放出、冷陰極、ショットキー電子源を駆動するために必要な統合フローティングフィラメント、エクストラクター、サプレッサー出力を備えています。すべての出力は、超低出力リップル、最小の微小放電、優れたレギュレーション、安定性、温度係数、および前例のない画質と解像度の精度仕様で提供されます。それぞれのフローティングソースの分離と制御は、スペルマン独自の高圧分離技術によって提供されます。

この統合されたEBM-FEG電源システムのお客様による制御は、光ファイバーRS-232インターフェースを介して行われます。すべての高圧安全インターロックは、フェイルセーフハードウェアベースの設計です。ユニットはULおよびCEマークが付けられており、SEMI規格に準拠するように設計されています。

用途走査型電子顕微鏡(SEM)

電子ビームコントローラー

Specifications

(Ref. 128136-001 REV. C)

Specifications

Input Voltage:

+24Vdc, ±5% @ 4 amps maximum. Inrush is <6 amps for 1 second.

Environmental:

Operating Temperature: +10°C to +45°C ambient for normal operation. The unit will operate from 0°C but will require an extended warm up period.

Storage Temperature:

-20°C to +60°C

Humidity:

0 to 80% RH, non-condensing

Altitude:

2000 meters ASL at full power. For altitudes above 2000 meters the maximum ambient operating temperature is linearly derated by 1.1˚C per 300 meter interval.

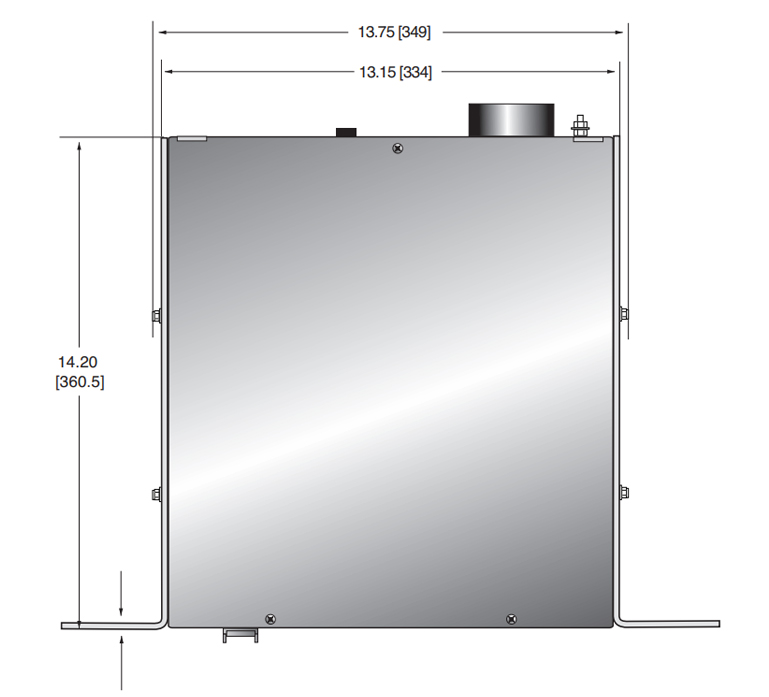

Mechanical:

The unit is provided with a pair of removable mounting flanges; these allow the unit to mount in a 19” rack system. The unit can be operated in any orientation.

Vacuum Interlock:

The vacuum interlock is an optical interlock which is made when light is present on the fiber. When no light is present the interlock is broken and the unit disables all of the outputs.

Front Panel Indicators:

Power On:

An illuminated green LED indicates that +24V power is present and it will be illuminated over the range 22.8 to 25.2 volts and will flash with a 1 second period when out of range.

Vacuum Interlock:

An illuminated yellow LED indicates that the vacuum interlock is closed. The vacuum interlock LED must be illuminated for the unit to be able to generate high voltage.

Test GUI:

A product GUI can be provided free of charge for customer testing and development work.

Protection:

All outputs are protected from arcs in the load and continuous short circuit to ground and between each other.

All low voltage inputs are protected against over voltages of ±30 volts. The power input is protected against over voltage and reversed connection.

If the Beam Energy has more than ‘A’ arcs in a nominal ‘B’ time (sec) period the unit will disable all outputs and sets all programs to zero.

If there are less than ‘A’ arcs the unit will continue to operate. The default values are A = 8 and B = 10. Both ‘A’ and ‘B’ are settable via optical bus commands and GUI.

In case of an over temperature condition for greater than ten seconds all outputs will be disabled.

The unit reports fault or trip conditions through status flags. After a Trip occurs (arc, over current, over voltage, temperature etc.), the unit can be reset through software (optical bus command) or power cycle.

Weight:

44 lbs. (20kg)

Regulatory Approvals:

UL recognized component (RC). File number E354595. Compliant to IEC/UL 61010-1 Safety requirements for electrical equipment for measurement, control and laboratory use; CAN/CSA-C22.2 No.61010-1. CE marked to EN 61010-1. UKCA marked to BS EN 61010-1. RoHS compliant.

As the unit is designed for incorporation within the user’s system it is not tested against any specific EMC standards. The user will need to take appropriate EMC precautions when designing the unit in and verify the overall system EMC performance against any relevant standards.

OUTPUT SPECIFICATIONS

| OUTPUT | Beam Energy | Filament | Suppressor | Extractor |

|---|---|---|---|---|

| Output Voltage | -20V to -30kV referenced to ground. Amplitude does not exceed 35kV and is <60 V when output disabled. Conditioning voltage -32.5kV at zero load current. | nominal 1.8V max 3V referenced to Beam Energy | -100V to -1kV referenced to Beam Energy | 100V to 10kV referenced to Beam Energy |

| Output current - max | 200μA | 3A | 100μA | 700μA |

| Current Trip | 250μA ±10% for 1s Output disabled and program set to zero |

>3.15A for 10s All outputs disabled and programs set to zero | >100mA ±10% for 5s. All outputs disabled and programs set to zero | Programmable 0 to 735μA. All outputs disabled and programs set to zero |

| Accuracy | <1% or ±10V (whichever is greater) | ±5mA (between 2A to 3A) | <2% or ±6V (whichever is greater) | <1% or ±20V (whichever is greater) |

| Linearity | <± 25V | ±10mA (between 0.5A to 3A) | ±5V | ±20V |

| Load Regulation | <±100mV for 30μA to 200μA | <5mA for 0.4Ω to 1Ω change at 3A | <120mV for 10μA to 100μA | <100mV at 40μA 0.1Hz to 20MHz, <1V at 10 - 700μA |

| Line Regulation for a ± 5% line change | <10ppm | <1mA | <5ppm | <5ppm |

| Ripple p-p at max. output | <50mVp-p 0.1Hz to 20MHz | <1mAp-p 20Hz to 10kHz <30mVp-p at approx 100kHz |

<20mVp-p at 0.1Hz to 20MHz | <100mV p-p at 0.1Hz to 20MHz |

| Temperature Coefficient | <5 ppm/°C from 20°C to 30°C, <10 ppm/°C otherwise | <50 ppm/°C | <50 ppm/°C | <25 ppm/°C |

| Stability (1h warm up) | 200mV/15min | <0.5mA/60min | <0.3V/15min | <0.3V/15min |

| Ramp Rate Programable Range |

50 to 5000 V/s | 1 to 3000 mA/s | 10 to 1000 V/s | 10 to 1000 V/s |

| Voltage Monitor Resolution | 0.5V | 2.5mV | 0.25V | 2.5V |

| Voltage Monitor Accuracy | ±2% or ±10V | ±5% or ±25mV | ±2% or ±250mV | ±1% or ±20V |

| Current Monitor Resolution | 100nA | 1mA | 0.25μA | 0.25μA |

| Current Monitor Accuracy | ±2% or ±1μA | ±10mA | ±10% | ±2% or ±2μA |

| Additional info | Programmable Wobble feature. Sinusoidal, amplitude up to 5% Beam Energy voltage, 0.5Hz to 1.6Hz |

Open Circuit detection: Vout > 5.2 ± 0.1V All outputs disabled and programs set to zero. Filament supply optimized for a nominal load resistance of 0.6Ω |

INPUT POWER CONNECTOR

UNIVERSAL MATE-N-LOK 1-350942-0

| Pin | Signal | Signal Parameters |

|---|---|---|

| 1 | +24Vdc | +24Vdc @ 4A |

| 2 | Power Ground | Power Ground |

VACUUM INTERLOCK CONNECTOR

The vacuum interlock connector is a dual channel Avago

HFBR- 2524z/1524z connector.

OPTICAL COMMUNICATIONS CONNECTOR

The fiber optics communications connector is a dual channel Avago HFBR- 2524z/1524z connector. A suitable Serial to optical communication kit including fiber optic cables, optic to RS-232 converter, RS-232 extension lead and RS-232 to USB cable is available. Optical to RS-232 converter can be ordered separately.

See HOW TO ORDER table

HIGH VOLTAGE OUTPUT CONNECTOR

The unit uses a custom high voltage 4 pole receptacle. A mating cable assembly in different lengths is available.

See HOW TO ORDER table.

HOW TO ORDER

| Description | Part Number |

|---|---|

| EBM-FEG | EBM30N6/FEG |

| Optical to RS-232 Communication Kit | EBMKFEG |

| Optical to RS-232 Converter (included in the above kit) | 21777 |

| HV Output Cable - 1.5 meters | HVC30/4ISO/1201 |

| HV Output Cable - 2.8 meters | HVC30/4ISO/1197 |

Tables & Diagrams

DIMENSIONS: in.[mm]

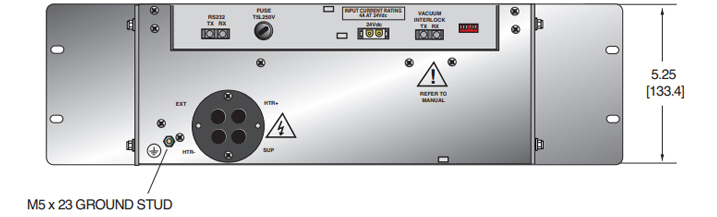

REAR VIEW

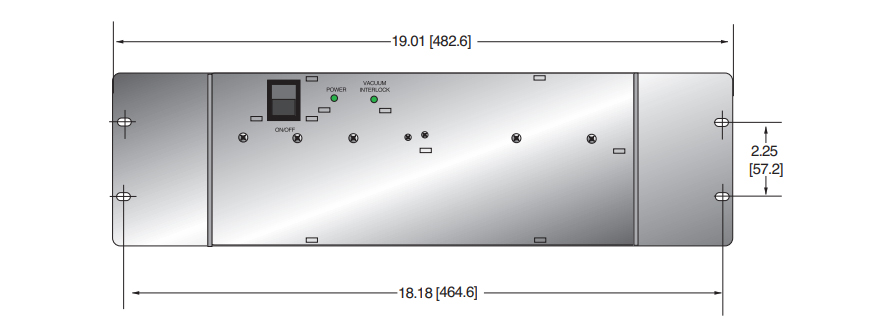

TOP VIEW

FRONT VIEW