Интегрированный рентгеновский источник XRBHR Monoblock® СЕРИЯ

- Компактные и легкие

- Работа при различном напряжении питания, корректировка коэффициента мощности

- Монтаж в любом положении

- Аналоговый интерфейс контроля, стандартный цифровой интерфейс RS-232, поддержка сети Ethernet

- Data Logging and Firmware Controlled X-Ray Tube Seasoning

*Примечание: Все спецификации могут быть изменены без предварительного уведомления. Пожалуйста, ознакомьтесь с английской версией PDF этой спецификации для получения последней актуальной информации об оборудовании.

ИСТОЧНИКИ РЕНТГЕНОВСКОГО ИЗЛУЧЕНИЯ МОЩНОСТЬЮ 100, 210, 350 И 500 ВТ

Spellman: серия XRBHR Monoblock® высокой надежности. Источники рентгеновского излучения предназначены для питания оборудования, изготавливаемого по спецификациям заказчика: биполярных рентгеновских генераторов, рассчитанных на напряжение 80 и 100 кВ и мощность 100, 210, 350 и 500 Вт. Такие особенности, как универсальный вход, компактная упаковка и стандартный цифровой интерфейс RS-232, упрощают интеграцию любой модели XRBHR в рентгеновскую систему. Для каждой модели XRBHR выпускаются блоки с веерным или коническим пучком излучения. Патентованная технология управления эмиссией посредством электронных устройств обеспечивает высокую точность сигнала тока, подаваемого на рентгеновскую трубку, и непревзойденную стабильность выходных характеристик. Серия XRBHR рассчитана на длительный срок службы и имеет 3х-летнюю гарантию.

ТИПОВЫЕ ВАРИАНТЫ ПРИМЕНЕНИЯ

Системы контроля качества пищевых продуктов, уровнемеры, системы сканирования, промышленные системы неразрушающего контроля, приборы для измерения толщины металлических покрытий.

Технические характеристики

(Ref. 128132-001 REV. U)

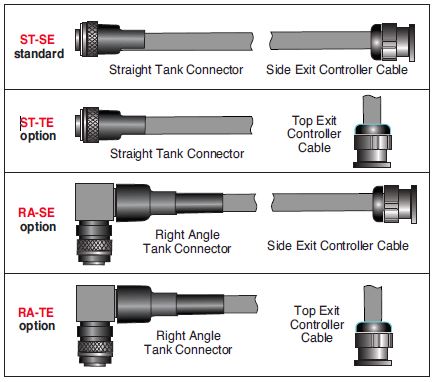

Options:

CB Cone Beam

.5mm .5mm focal spot X-Ray tube

ST-TE See Cable Options

RA-SE See Cable Options

RA-TE See Cable Options

SPECIFICATIONS

X-Ray Characteristics:

Focal Spot: 0.8mm (IEC 336)

0.5mm (IEC 336) optional

Beam Filter:

Ultem: 1.50mm ±0.15mm

Oil: 9.0mm ±0.25mm

Glass: 1.7mm ±0.2mm

Be: 0.8mm

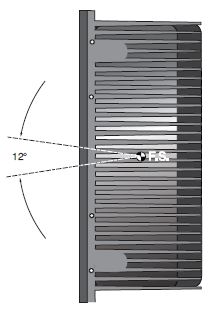

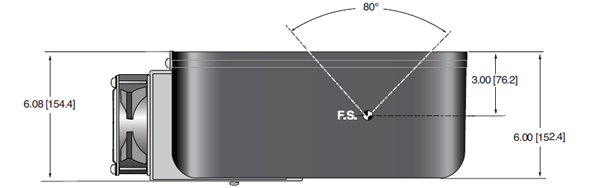

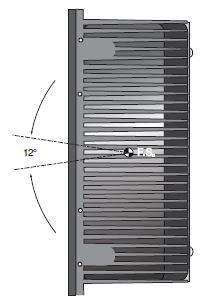

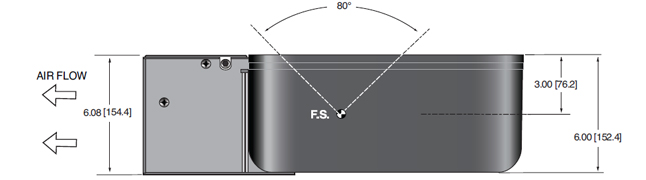

Beam Geometry:

Fan: Standard. The beam angular coverage will be 90° with the beam plane perpendicular to the X-Ray tube axis and 12° wide (with a 2° tolerance)

Cone: Optional. 40° cone beam (with a 2° tolerance)

Input Voltage:

100-240Vac, ±10%, 50/60 Hertz, .98 power factor

Input Current:

100W @ 2A

210W @ 4A

350W @ 6A

500W @ 8A

X-Ray Tube Voltage:

See table

X-Ray Tube Current:

See table

X-Ray Tube Power:

See table

Operating Temperature:

0°C to +40°C

Storage Temperature:

-40°C to +70°C

Humidity:

10% to 95% relative humidity, non-condensing

Cooling:

0.5% peak to peak of maximum voltage for frequencies ≤1kHz

Emission Current Parameters

Current Regulation:

Line: ±0.05% of rated output current over a ±10% change of nominal input line voltage

Load: ±0.1% of rated output current for a change from 50% to 100% of rated output voltage

Current Accuracy:

Current measured through the X-Ray tube is within ±2% of the programmed value

Current Risetime:

Standard: Ramp time shall be <500ms from 10% to 90% of maximum rated current

Arc Intervention:

4 arcs in 10 seconds with a 100ms quench/100ms re-ramp = Shutdown

Filament Configuration:

Internal AC filament drive with closed loop filament emission control

Analog Interface:

Ground referenced 0 to 9Vdc for all monitoring signals.

Relay contacts and open collector signals for other signals. See analog interface connector pin out table.

Digital Interface:

The RS-232 interface allows for programming of kV, mA output and X-Ray enable. Provides monitoring for kV, mA output and oil temperature. Tolerance 3%. (with an additional 5μA offset at ≤10% mA programming)

Operating Temperature:

0°C to +40°C

Storage Temperature:

-40°C to +70°C

Humidity:

10% to 95% relative humidity, non-condensing

Cooling:

X-Ray Tank:

100W: Convection/customer supplied forced air so tank is < 55˚C

210W: Externally powered forced air cooling, 24Vdc @ 2A

350W: Externally powered forced air cooling with oil pump and heat exchanger, 24Vdc @ 5A

500W: Externally powered forced air cooling with oil pump and heat exchanger, 24Vdc @ 5A

Controller: Forced air via internal fan.

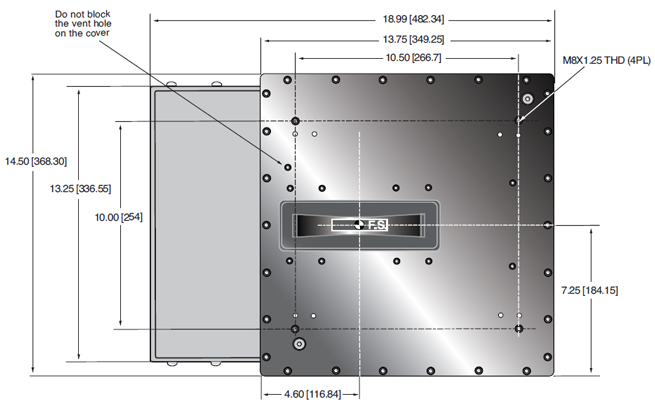

Grounding Point:

M5 ground female thread on tank

M5 ground stud on control chassis provided

Dimensions:

X-Ray Tank: See drawings

100W/210W Controller: See drawings

350W/500W Controller: See drawings

Weight:

X-Ray Tank:

100W @ 75 lbs. (34kg)

210W @ 75lbs. (34kg)

350W @ 81.5lbs. (37kg)

500W @ 81.5lbs. (37kgs)

Orientation:

Can be mounted in any orientation.

X-Ray Leakage:

Not to be greater than 0.5mR/hr at 5cm outside the external surface.

Regulatory Approvals:

Compliant to EEC EMC Directive. Compliant to EEC Low Voltage Directive. UL/CUL recognized file E235530

MODEL SELECTION TABLE

| Model | Maximum Voltage | Maximum Current | Maximum Power |

|---|---|---|---|

| XRB80PN210HR | 80kV | 5.25mA | 210 watts |

| XRB80PN350HR | 80kV | 8mA | 350 watts |

| XRB80PN500HR | 80kV | 8mA | 500 watts |

| XRB100PN100HR | 100kV | 2mA | 100 watts |

| XRB100PN210HR | 100kV | 4.2mA | 210 watts |

| XRB100PN350HR | 100kV | 7mA | 350 watts |

| XRB100PN500HR | 100kV | 8mA | 500 watts |

LED INDICATORS for 100W and 200W Units

| INDICATOR | SIGNAL | CONDITION Illuminated When... | LED COLOR |

|---|---|---|---|

| 1 | OV Error 6 | High kV occurs | Red |

| 2 | UV Error 5 | Low kV occurs | Red |

| 3 | UC Error 4 | Low mA occurs | Red |

| 4 | Power On | AC input power is present | Green |

| 5 | OC Error 3 | High mA occurs | Red |

| 6 | ARC Error 2 | Arc fault occurs | Red |

| 7 | OT Error 1 | Over temperature occurs | Red |

| 8 | X-Ray On | X-Rays are being generated | Green |

LED INDICATORS for 350W and 500W Units

| INDICATOR | SIGNAL | CONDITION Illuminated When... | LED COLOR |

|---|---|---|---|

| 1 | OV Error 6 | High kV occurs | Red |

| 2 | UV Error 5 | Low kV occurs | Red |

| 3 | UC Error 4 | Low mA occurs | Red |

| 4 | OC Error 3 | High mA occurs | Red |

| 5 | ARC Error 2 | Arc fault occurs | Red |

| 6 | OT Error 1 | Over temperature occurs | Red |

| 7 | X-Ray On | X-Rays are being generated | Green |

| 8 | Power On | AC input power is present | Green |

| SMART XRB |

||

|---|---|---|

|

The XRBHR has two new digital features: data logging and firmware controlled seasoning. Data Logging: FAULT EVENTS The XRBHR stores data 620ms before the event, the event itself and for 620ms after the event. Data is recorded every 20ms (62 samples total) showing: We also log non-fault events, these are changes in set points or state of the unit. NON FAULT EVENTS Fault event data is actual graphical data. Non fault event data is just stored as event type, data and timestamp. We also have a preventative maintenance fault, which throws a non-shutdown fault if the X-Ray tube has been factory Firmware Controlled Seasoning: |

Power and Interface Connections for 100W and 210W Units

AC Input—6 PIN MOLEX 09-50-8061

| PIN | SIGNAL PARAMETERS | |

|---|---|---|

| 1 | AC Input (high) | 100-240Vac (high) |

| 2 | Pin Removed | N/C |

| 3 | AC Input (neutral) | 100-240Vac (neutral) |

| 4 | Pin Removed | N/C |

| 5 | N/C | N/C |

| 6 | N/C | N/C |

ANALOG INTERFACE—7 PIN MOLEX 09-50-8071

| PIN | SIGNAL | PARAMETERS |

|---|---|---|

| 1 | X-Ray Interlock Enable | Apply +24Vdc to enable interlock. Open/removal of +24Vdc will cause X-Ray generation to stop |

| 2 | X-Ray Interlock Enable Return | Ground reference for X-Ray Interlock |

| 3 | Pin removed | N/C |

| 4 | kV Monitor | 0-10Vdc = 0-100% rated output voltage. Zout = 10kΩ |

| 5 | Signal Ground | Signal Ground |

| 6 | mA Monitor | |

| 7 | X-Ray On | Open collector, High (Open) = No Fault, 35Vdc @10mA maximum |

RS-232 DIGITAL INTERFACE— 9 PIN MALE D CONNECTOR

| PIN | SIGNAL | PARAMETERS |

|---|---|---|

| 1 | N/C | N/C |

| 2 | Transmitted Data | Conforms to EIA RS-232-C |

| 3 | Received Data | Conforms to EIA RS-232-C |

| 4 | N/C | N/C |

| 5 | Signal Ground | Signal Ground |

| 6 | N/C | N/C |

| 7 | N/C | N/C |

| 8 | N/C | N/C |

| 9 | N/C | N/C |

ETHERNET DIGITAL INTERFACE— RJ45 8 PIN FEMALE CONNECTOR

| PIN | SIGNAL | PARAMETERS |

|---|---|---|

| 1 | TX + | Transmit Data + |

| 2 | TX - | Transmit Data - |

| 3 | RX + | Receive Data + |

| 4 | N/C | No Connection |

| 5 | N/C | No Connection |

| 6 | N/C | Receive Data - |

| 7 | N/C | No Connection |

| 8 | N/C | No Connection |

HV LAMP ON RELAY—3 PIN MOLEX 09-50-8031

| PIN | SIGNAL | PARAMETERS |

|---|---|---|

| 1 | Normally Closed dry contact | 50V max. Rated for 1 amp or less, 50mA nominal load |

| 2 | Common | 50V max. Rated for 1 amp or less, 50mA nominal load |

| 3 | Normally Open dry contact | 50V max. Rated for 1 amp or less, 50mA nominal load |

Power and Interface Connections for 350W and 500W Units

AC INPUT—3 PIN PHOENIX CONTACT 1858772

| PIN | SIGNAL PARAMETERS | |

|---|---|---|

| 1 | AC Input (high) | 100-240Vac (high) |

| 2 | Ground | Ground |

| 3 | AC Input (neutral) | 100-240Vac (neutral) |

DC INPUT FOR HEAT DISSIPATION UNIT—4 PIN AMP (210/350/500W) 206060-1

| PIN | SIGNAL | DESCRIPTION | PARAMETERS |

|---|---|---|---|

| 1 | 24Vdc | Fan/Pump Power | 24Vdc @ 5 amps |

| 2 | 24Vdc Return | Fan/Pump Power | 24Vdc @ 5 amps |

| 3 | N/C | No Connection | N/C |

| 4 | N/C | No Connection | N/C |

“It is critical to ensure that 24Vdc is supplied to pins 1 and 2”

ANALOG INTERFACE— 10 PIN PHOENIX CONTACT 1792605

| PIN | SIGNAL | PARAMETERS |

|---|---|---|

|

1 |

X-Ray Interlock Enable | Apply +24Vdc to enable interlock. Open/removal of +24Vdc will cause X-Ray generation to stop. |

| 2 | X-Ray Interlock Enable Return | Ground reference for X-Ray Interlock. |

| 3 | Pin removed | N/C |

| 4 | kV Monitor | 0-10Vdc = 0-100% rated output voltage. Zout = 10kΩ |

| 5 | Signal Ground | Signal Ground |

| 6 | mA Monitor | 0-10Vdc = 0-100% rated output current. Zout =10kΩ |

| 7 | Fault Signal | Open collector, High (Open) = No Fault, 35Vdc @ 10mA maximum |

| 8 | HV ON Lamp Relay N/O | N/O dry contacts. 50 volts maximum. Rated for 1 amp or less, 50mA nominal load |

| 9 | HV ON Lamp Relay C | Common dry contacts. 50 volts maximum. Rated for 1 amp or less, 50mA nominal load |

| 10 | HV ON Lamp Relay N/C | N/C dry contacts. 50 volts maximum. Rated for 1 amp or less, 50mA nominal load |

RS-232 DIGITAL INTERFACE— 9 PIN MALE D CONNECTOR

| PIN | SIGNAL | PARAMETERS |

|---|---|---|

| 1 | N/C | N/C |

| 2 | Transmitted Data | Conforms to EIA RS-232-C |

| 3 | Received Data | Conforms to EIA RS-232-C |

| 4 | N/C | N/C |

| 5 | Signal Ground | Signal Ground |

| 6 | N/C | N/C |

| 7 | N/C | N/C |

| 8 | N/C | N/C |

| 9 | N/C | N/C |

ETHERNET DIGITAL INTERFACE— RJ45 8 PIN FEMALE CONNECTOR

| PIN | SIGNAL | PARAMETERS |

|---|---|---|

| 1 | TX + | Transmit Data + |

| 2 | TX - | Transmit Data - |

| 3 | RX + | Receive Data + |

| 4 | N/C | No Connection |

| 5 | N/C | No Connection |

| 6 | RX - | Receive Data - |

| 7 | N/C | No Connection |

| 8 | N/C | No Connection |

Таблицы и диаграммы

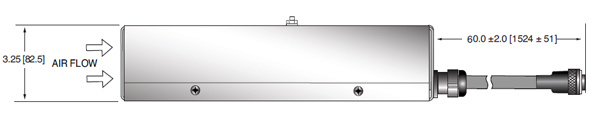

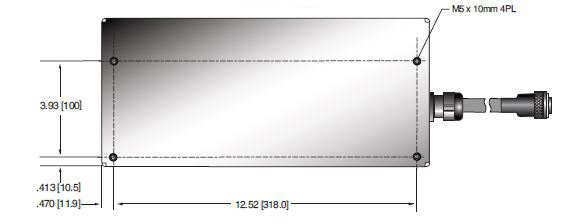

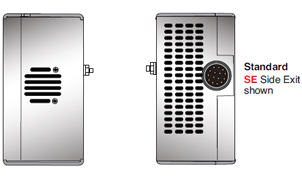

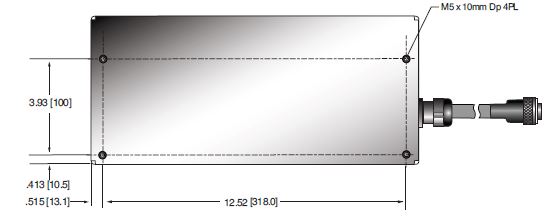

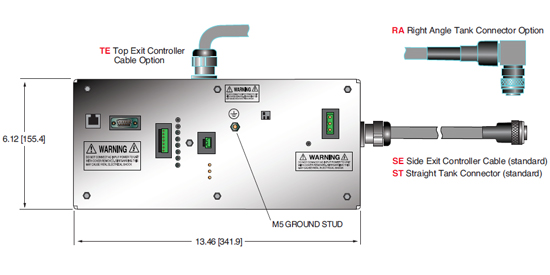

DIMENSIONS: in.[mm]

100/210W

CONTROL UNIT

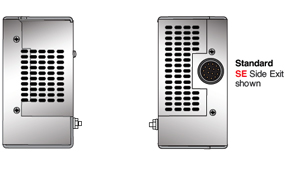

FRONTVIEW

BOTTOM VIEW

REAR VIEW

SIDE VIEW

Cable Configurations

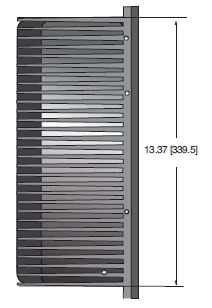

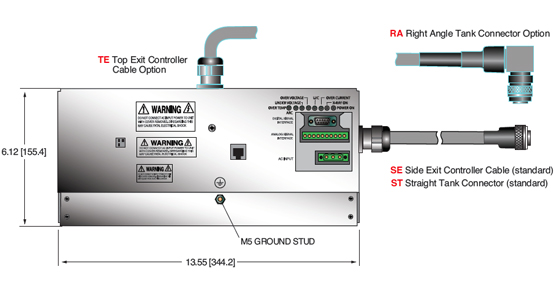

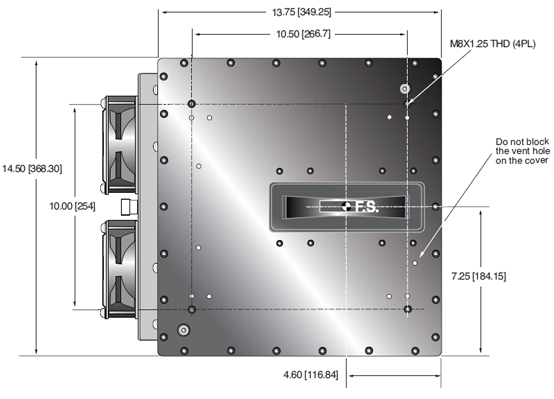

DIMENSIONS: in.[mm]

300/500W CONTROL UNIT

FRONT VIEW

BOTTOM VIEW

SIDE VIEW

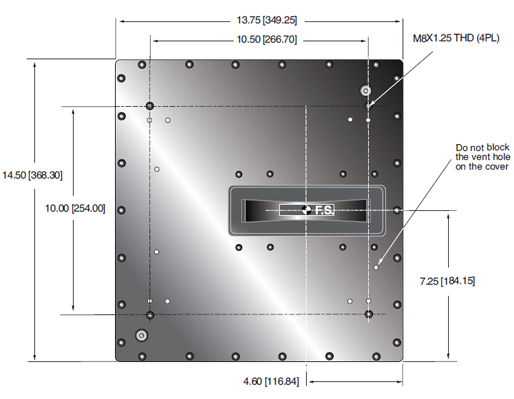

DIMENSIONS: in.[mm]

100W TANK

TOP VIEW

SIDE VIEW

BACK VIEW

FRONT VIEW

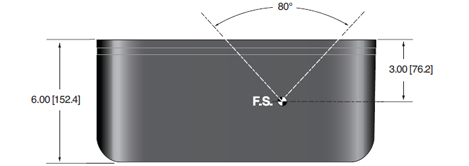

DIMENSIONS: in.[mm]

210W TANK

TOP VIEW

SIDE VIEW

BACK VIEW

FRONT VIEW

DIMENSIONS: in.[mm]

350/500W TANK

TOP VIEW

SIDE VIEW

BACK VIEW

FRONT VIEW

Frequently Asked Questions

Why Is Oil Insulation Used?

Do I Need to Ensure My Monoblock® Stays Cool? Why?

How Often Do I Need to Season My Monoblock® X-Ray Source? Why?

Application Notes AN-12 – The Benefit of Using a Current Source to Power X-Ray Tube Filament Circuits