XRBe80PN300 Monoblock® Integrated X-Ray Source

- Compact & Lightweight

- Universal Input, Power Factor Corrected

- Can be Mounted in Any Physical Orientation

- Analog Monitoring Interface, Standard RS-232 Digital Interface and Ethernet

- Data Logging and Firmware Controlled X-Ray Tube Seasoning

*Note: All specifications are subject to change without notice. Please consult the English PDF version of this datasheet for the most up-to-date revision.

80KV/300W Be Window Monoblock®

Spellman’s XRBe80PN300 beryllium window Monoblock® X-Ray sources are designed for OEM applications powering the internal Bipolar X-Ray tube at 80kV at a power level of 300W. Features such as universal input, compact package size and a standard RS-232 digital interface simplify integration of the XRBe80PN300 into your X-Ray system. It is available with a cone shaped beam geometry. Proprietary emission control circuitry provides excellent regulation of X-Ray tube current, along with outstanding stability performance.

TYPICAL APPLICATIONS

Food Inspection Systems, Fill Level Confirmation Systems, Security Scanning Systems, Industrial NDT Systems, Thickness/Plating Measurement Systems

사양

(Ref. 128132-001 REV. C)

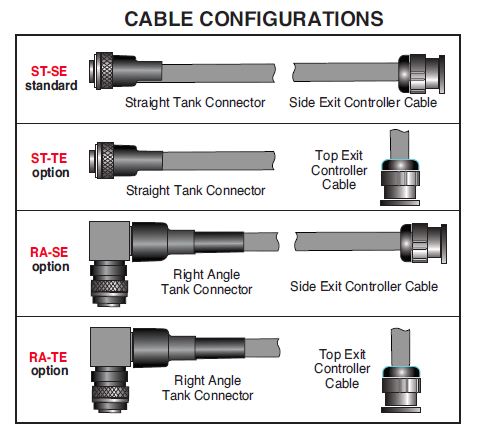

Options:

ST-TE, RA-SE, RA-TE Cable Options (see page 3 of the data sheet)

SPECIFICATIONS

X-Ray Characteristics:

Focal Spot: 0.8mm (IEC 336) standard

Beam Filter: Be 0.8mm

Beam Geometry:

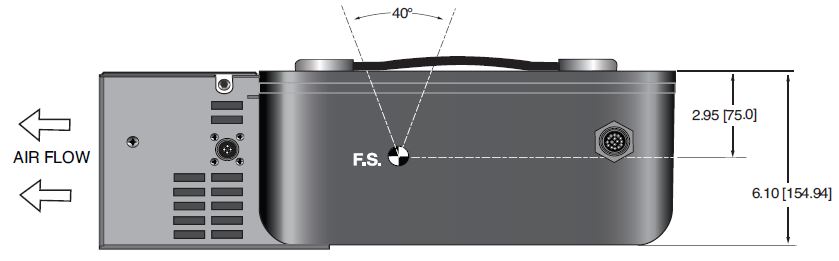

Cone: Standard. The beam angular coverage will be 40° with the beam plane perpendicular to the X-Ray tube axis

Input Voltage:

100- 240Vac, ±10%, 50/60 Hertz, .98 power factor

Input Current:

300W @ 6A

X-Ray Tube Voltage:

Maximum 80kV

X-Ray Tube Current:

Maximum 5mA

X-Ray Tube Power:

300W

Voltage Regulation:

Line: Line:±0.05% of maximum output voltage over a ±10% change of nominal input line voltage

Load: ±0.1% of maximum rated voltage for 150uA to full rated load change

Voltage Accuracy:

Voltage measured across the X-Ray tube is within ±2% of the programmed value

Voltage Risetime:

Standard ramp time shall be <500ms from 10% to 90% of maximum rated output voltage

Voltage Ripple:

0.5% peak to peak of maximum voltage forfrequencies ≤1kHz

X-Ray Tube Voltage:

Maximum 80kV

Emission Current Parameters

Current Regulation:

Line: ±0.05% of rated output current over a ±10% change of nominal input line voltage

Load: ±0.1% of rated output current for a change from 50% to 100% of rated output voltage

Current Risetime:

Standard ramp time shall be <500ms from 10% to 90% of maximum rated current

Arc Intervention:

4 arcs in 10 seconds with a 100ms quench/100ms re-ramp = Shutdown

Filament Configuration:

Internal floating AC filament drive with closed loop filament emission control circuitry

Analog Interface:

Ground referenced 0 to 9Vdc for all monitoring signals. Relay contacts and open collector signals for other signals. See analog interface connector pinout table.

Digital Interface:

The RS-232 interface allows for programming of kV, mA output and X-Ray enable. Provides monitoring for kV, mA output and oil temperature.

Operating Temperature:

0°C to +40°C

Storage Temperature:

-40°C to +70°C

Humidity:

10% to 95% relative humidity, non-condensing

Cooling:

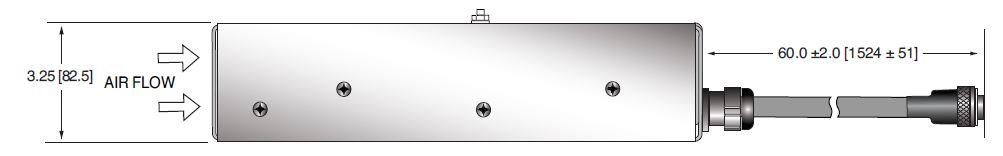

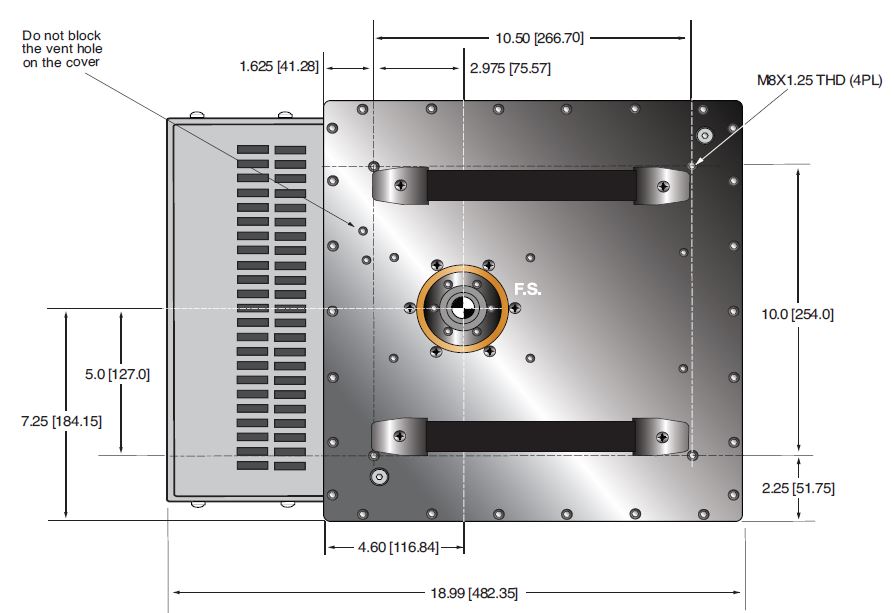

X-Ray Tank: Externally powered forced air cooling with oil pump and heat exchanger, 24Vdc @ 5A

Controller: Forced air via internal fan.

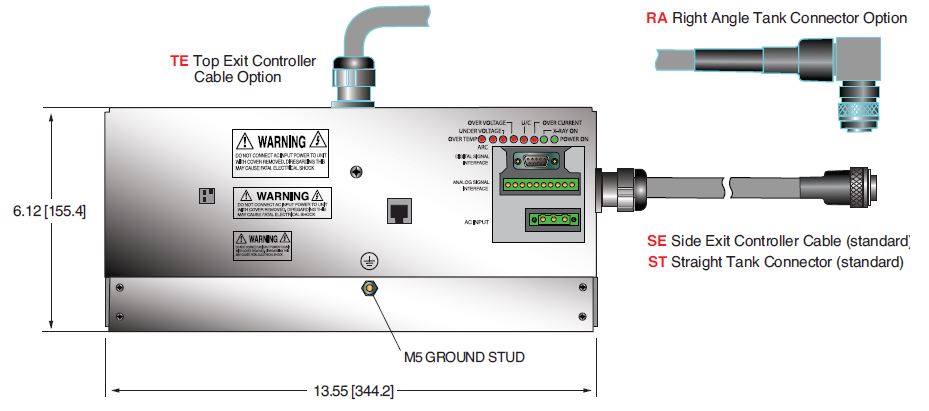

Grounding Point:

M5 ground female thread on tank

M5 ground stud on control chassis provided

Dimensions:

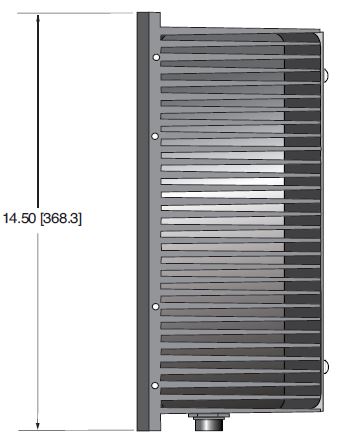

X-Ray Tank: See drawings

Controller: See drawings

Weight:

X-Ray Tank:

81.5 lbs. (37kg)

Controller:

7 lbs. (3.18kg)

Orientation:

Can be mounted in any orientation.

X-Ray Leakage:

Not to be greater than 0.5mR/hr at 5cm outside the external surface.

Regulatory Approvals:

Compliant to EEC EMC Directive. Compliant to EEC Low Voltage Directive. UL/CUL recognized file E235530.

AC INPUT—3 PIN PHOENIX CONTACT 1858772

| PIN | SIGNAL | PARAMETERS |

|---|---|---|

| 1 | AC Input (high) | 100-240Vac (high) |

| 2 | Ground | Ground |

| 3 | AC Input (neutral) | 100-240Vac (neutral) |

DC INPUT FOR HEAT DISSIPATION UNIT—4 PIN AMP(210/350/500W) 206060-1

| PIN | SIGNAL | DESCRIPTION | PARAMETERS |

|---|---|---|---|

| 1 | 24Vdc | Fan/Pump Power | 24Vdc @ 5 amps |

| 2 | 24Vdc Return | Fan/Pump Power |

24Vdc @ 5 amp s |

| 3 | N/C | No Connection | N/C |

| 4 | N/C | No Connection | N/C |

It is critical to ensure that 24Vdc is supplied to pins 1 and 2

LED INDICATORS

| INDICATOR | SIGNAL | CONDITION Illuminated When... | LED COLOR |

|---|---|---|---|

| 1 | OV Error 6 | High kV occurs | Red |

| 2 | UV Error 5 | Low kV occurs | Red |

| 3 | UC Error 4 | Low mA occurs | Red |

| 4 | OC Error 3 | High mA occurs | Red |

| 5 | ARC Error 2 | Arc fault occurs | Red |

| 6 | OT Error 1 | Over temperature occurs | Red |

| 7 | X-Ray On | X-Rays are being generated | Green |

| 8 | Power On | AC input power is present | Green |

ANALOG INTERFACE—10 PIN PHOENIX CONTACT 1792605

| PIN | SIGNAL | PARAMETERS |

|---|---|---|

| 1 | X-Ray Interlock Enable | Apply +24Vdc to enable interlock. Open/removal of +24Vdc will cause X-Ray generation to stop. |

| 2 | X-Ray Interlock Enable Return | Ground reference for X-Ray Interlock. |

| 3 | Pin Removed | N/C |

| 4 | kV Monitor | 0-10Vdc = 0-100% rated output voltage. Zout = 10kΩ |

| 5 | Signal Ground | Signal Ground |

| 6 | mA Monitor | 0-10Vdc = 0-100% rated output current. Zout =10kΩ |

| 7 | Fault Signal | Open collector, High (Open) = No Fault, 35Vdc @ 10mA maximum |

| 8 | HV ON Lamp Relay N/O | N/O dry contacts. 50 volts maximum. Rated for 1 amp or less, 50mA nominal load |

| 9 | HV ON Lamp Relay C | Common dry contacts. 50 volts maximum. Rated for 1 amp or less, 50mA nominal load |

| 10 | HV ON Lamp Relay N/C | N/C dry contacts. 50 volts maximum. Rated for 1 amp or less, 50mA nominal load |

RS-232 DIGITAL INTERFACE—9 PIN MALE D CONNECTOR

| PIN | SIGNAL | PARAMETERS |

|---|---|---|

| 1 | N/C | N/C |

| 2 | Transmitted Data | Conforms to EIA RS-232-C |

| 3 | Received Data | Conforms to EIA RS-232-C |

| 4 | N/C | N/C |

| 5 | Signal Ground | Signal Ground |

| 6 | N/C | N/C |

| 7 | N/C | N/C |

| 8 | N/C | N/C |

| 9 | N/C | N/C |

ETHERNET DIGITAL INTERFACE—RJ45 8 PIN FEMALE CONNECTOR

| PIN | SIGNAL | PARAMETERS |

|---|---|---|

| 1 | TX+ | Transmit Data + |

| 2 | TX- | Transmit Data- |

| 3 | RX+ | Receive Data + |

| 4 | N/C | No Connection |

| 5 | N/C | No Connection |

| 6 | RX- | Receive Data - |

| 7 | N/C | No Connection |

| 8 | N/C | No Connection |

| SMART XRB |

|---|

|

The XRBD has two new digital features: data logging and firmware controlled seasoning. Data Logging: Think of this as an “airplane black box”. The data logging captures data on fault events and non-fault events. Fault events will turn off the high voltage: FAULT EVENTS Temperature The XRBe80PN300 stores data 620ms before the event, the event itself and for 620ms after the event. Data is recorded every 20ms (62 samples total) showing: Anode kV We also log non-fault events, these are changes in set points or state of the unit. NON FAULT EVENTS HV On Fault event data is actual graphical data. Non fault event data is just stored as event type, data and timestamp. We also have a preventative maintenance fault, which throws a non-shutdown fault if the X-Ray tube has been factory installed over 4 years ago or if over 15,000 hours of HV ON is logged. Firmware Controlled Seasoning: Every unit comes with an initial seasoning table, or customers can set their own. The XRBe80PN300 knows when the unit has been on, when it has been off, hours on the X-Ray tube, etc. As a preventative maintenance feature upon turn on, we review the data and suggest that a particular seasoning protocol be run based upon the actual usage history of the unit. Proper seasoning compliance of the X-Ray tube will help get the longest lifetime. |

테이블 및 다이어그램

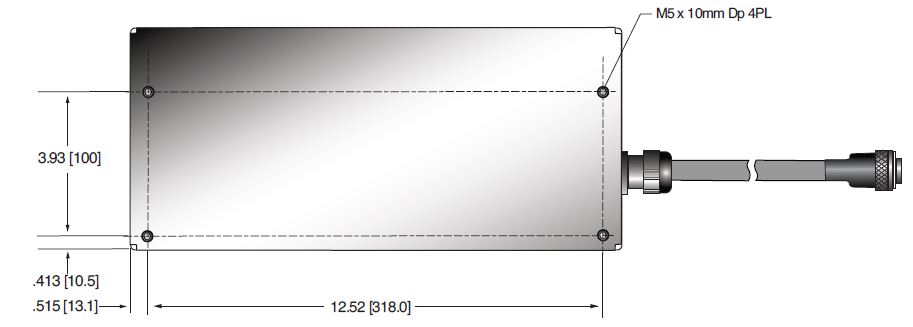

DIMENSIONS: in.[mm]

CONTROL UNIT

FRONTVIEW

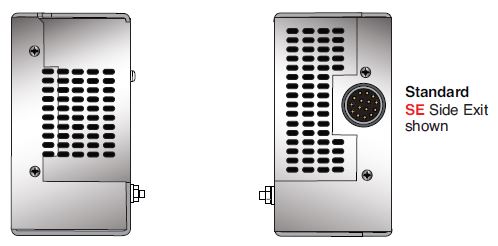

BOTTOM VIEW

REAR VIEW

SIDE VIEW

DIMENSIONS: in.[mm]

TOP VIEW

SIDE VIEW

FRONT VIEW