XRF Series

- 160kV Output Voltage

- Rack-Mountable

- Floating Filament

- Internal Grid Power Supply (80W Model)

- Power Factor Correction

- Closed-loop Emission Control

- OEM Customization Available

*Note: All specifications are subject to change without notice. Please consult the English PDF version of this datasheet for the most up-to-date revision.

80-640W Industrial X-Ray Generators

Spellman’s XRF Series x-ray generator allow for a wide range of input voltages and supply either 80W, 320W or 640W of output power at up to 160kVdc. These lightweight rack-mountable X-ray generators house a miniaturized high voltage system in a solid encapsulated, oil-free design. The XRF Series x-ray generator is designed with a power factor corrected input circuit which reduces harmonic emissions and noise normally associated with other high frequency switching power supplies. The XRF Series x-ray generator incorporates an internal floating filament and a closed-loop emission control circuit for precise regulation of emission current. Remote monitoring and control of voltage, current and filament current is also provided.

Typical uses of the XRF x-ray generator are:

- X-ray Inspection

- Non-Destructive Testing

Specifications

(Ref. 128013-001 REV. R)

Input Voltage:

80W: 90-125Vac at 48-62Hz @ 1.9A

180-264Vac at 48-62Hz @ 0.9A

320W: 180-264Vac at 48-62Hz @ 3.5A

640W: 180-264Vac at 48-62Hz @ 7A

Power Factor:

0.9 or better.

High Voltage Supply:

Output Voltage:

0-160kV, negative polarity.

Output Current:

80W: 0.5mA max. 320W: 2.0mA at 160kV 640W: 4.0mA.

Output Voltage Stability:

Within 0.1% of set value after warm-up period at full load.

Output Voltage Ripple:

80W & 320W: <0.1%, or 160V p-p for high freq. and line freq. at full load.

640W: 0.03% rms <1kHz, 0.75% rms above 1kHz.

Beam Current Stability

80W: Within 0.1% of set value after 1/2 hour warm-up at constant output setting of 30-160kV and line voltage of 90-125 & 180-264Vac.

320W & 640W: Same as 80W except line voltage of 180-264Vac.

Filament Supply: Constant current DC filament supply with closed-loop current feedback.

Filament Voltage: 7V rms (high frequency) max.

Filament Current: 5A max., adjustable 0-5.0A by external Filament Limit Programming input.

Floating Grid Power Supply:

Grid Supply: The grid supply controls tube beam current in a closed-loop regulation design.

Grid Voltage: 0 to 1200Vdc.

Grid Voltage Ripple: Less than 1.0V rms at any frequency.

Grid Supply Response: Less than 0.5mA in less than 10ms.

Control and Monitoring:

Analog Control Inputs: Three inputs have internal load resistance greater than 330kohms.

Voltage Programming:

80W, 320W & 640W:

0 to +10Vdc, where 10.0Vdc = 160kV output.

Beam Tube Current Control:

80W: 0 to +10Vdc, where 10.0Vdc = 0.5mA tube current.

320W: 0 to +10Vdc, where 10.0Vdc = 2.0mA tube current.

640W: 0 to +10Vdc, where 10.0Vdc = 4.0mA tube current.

Filament Current Control:

0 to +10Vdc, where 5.0Vdc = 5.0A filament current.

Analog Monitor Outputs: (See tables for details)

Digital Control Inputs: (See tables for details)

Digital Outputs: (See tables for details)

Connections:

Output Connector:

R24 (see owners manual for details)

Input Power Connector:

5-pin male MS-type, Amphenol P/N 97-3102A-18-20P

Control Connector:

25-pin “D” connector, male, chassis-mounted.

Environmental:

0 to +50°C at 10-95% RH, non-condensing.

Forced convection cooling.

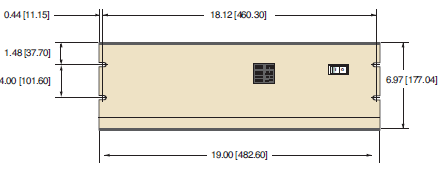

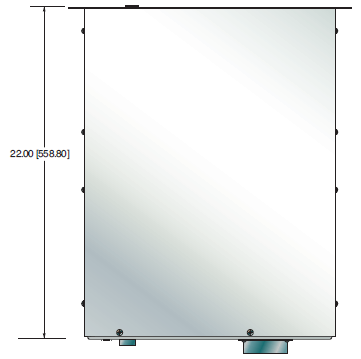

Dimensions:

7”H x 19”W x 22”D (17.8cm x 48.3cm x 55.9cm).

Regulatory Approvals:

Compliant to EEC EMC Directive. Compliant to EEC Low Voltage Directive. RoHS compliant

Options:

DF - Dual Filament AT - Arc Trip

GS - Grid Supply IO - Instant ON

SL - Slides SS(X) - Non Standard Slow Start

Electronic Component (Power Source)

XRF series is intended for installation as a component of a system. It is designed to meet CE standards, with conditions of acceptance often being: customer provided enclosure mounting, EMC filtering, and appropriate protection, and isolation devices. The XRF series is not intended to be operated by end users as a stand-alone device. The XRF series power supply can only be fully assessed when installed within a system, and as a component part within that system.

160kV XRF SELECTION TABLE

| Output Voltage kV | Output Current mA | Output Power W | Model Number XRFxxx |

|---|---|---|---|

| 160 | 0.5 | 80 | XRF160N80 |

| 160 | 2.0 | 320 | XRF160N320 |

| 160 | 4.0 | 640 | XRF160N640 |

J2 AC INPUT CONNECTOR WIRING

| 5 Pin MS Type | 7 Pin UTG Type | Connection |

|---|---|---|

| A | 1 | Auxiliary (Logic) Line |

| B | 2 | Auxiliary (Logic) Neutral |

| C | 3 | Ground |

| D | 4 | Main (Inverter) Line |

| E | 5 | Main (Inverter) Neutral |

JB1 160kV XRF 80W, 320W, 640W 25 PIN

| Pin | Signal | Signal Parameters |

|---|---|---|

| 1 | Filament Limit | 0-5V = 0-5A Filament Limit |

| 2 | High Voltage on Control | +12VDC IN = HV ON |

| 3 | N/C | |

| 4 | N/C | |

| 5 | High Voltage On Status | Low = HV ON |

| 6 | A-Ground | Ground |

| 7 | kV Monitor | 0-10V = 0-160kV |

| 8 | Interlock Control | +12VDC IN = Interlock Closed |

| 9 | N/C | |

| 10 | mA Demand | 0-10V = 0-100% Rated Output |

| 11 | N/C | |

| 12 | N/C | |

| 13 | D-Ground | Ground |

| 14 | Fil. Monitor | 0-5V = 0-5A |

| 15 | N/C | |

| 16 | N/C | |

| 17 | N/C | |

| 18 | N/C | |

| 19 | mA Monitor | 0-10V = 0-100% Rated Output |

| 20 | N/C | |

| 21 | +12VDC Out | |

| 22 | kV Demand | 0-10V = 0-160kV |

| 23 | Grid Inhibit/Fil. Select | Low = Grid Inhibit |

| 24 | N/C | |

| 25 | Chassis Gnd (I/O Shield) | Chassis Gnd. |

160kV XRF 80W, 320W, 640W TERMINAL BLOCK 10 PIN

| Pin | Signal | Signal Parameters |

|---|---|---|

| 1 | Interlock | Jumper to TB1-2 to close interlock |

| 2 | Interlock Return | |

| 3 | kV Monitor | 0-10V=0-160kV |

| 4 | mA Monitor | 0-10V = 0-100% Rated Output |

| 5 | Filament Monitor | 0-5V=0-5A |

| 6 | N/C | |

| 7 | HV ON Indicator | +15V = HV ON |

| 8 | Voltage Mode Indicator | Low = Voltage Mode. |

| 9 | Current Mode Indicator | Low = Current Mode. |

| 10 | GND | Ground |

Tables & Diagrams

DIMENSIONS: in.[mm]

FRONT VIEW

TOP VIEW

BACK VIEW

Frequently Asked Questions

Application Notes AN-12 – The Benefit of Using a Current Source to Power X-Ray Tube Filament Circuits

Application Notes AN-01 – Fundamentals of X-Ray Generator – X-Ray Tube Optimization